Thread grinding for international company

- Robert Cockroft

- Jul 20, 2020

- 1 min read

Westin Engineering continues to be first-choice supplier to an international subsea exploration product and service company.

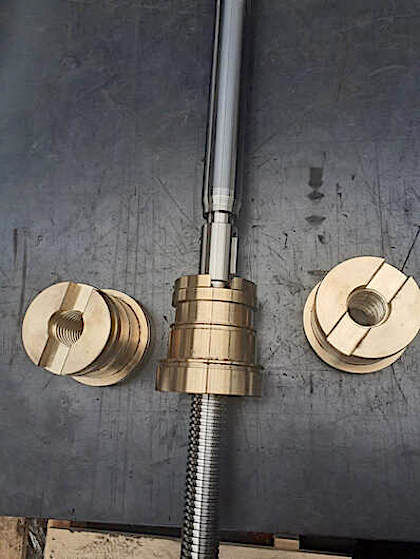

Stems manufactured from Inconel and other exotic alloys are sent to us for the final manufacturing process: thread grinding the screw on the stem and machining nuts and collars to match.

Quick turnaround is usually required for what is extremely high-end precision engineering and we pride ourselves on being up to the challenge. Stem lengths range from 300mm to 1250mm.

Meanwhile, we are regularly asked by local manufacturing and processing businesses to repair or reverse engineer components from faulty or broken machines.

Because many companies no longer carry equipment spares, rapid response is almost always required. We usually oblige and are rewarded by regular repeat business.

Recent examples of our work include:

Grinding a large damaged tapered shaft and machining a large bush to fit at the end

Manufacturing new gears for a wood cutting machine

Repairing and machining a small splined shaft and mating part

We are delighted that an established machine manufacturing business with a large export order book and time critical deadlines has started using us as their main component supplier.

Our new lathes with live tooling have enabled us to offer customers competitive pricing, outstanding quality and on-time delivery.

Comments